MGHZ1200 Electrical Control System

MGHZ1200 Electrical Control System

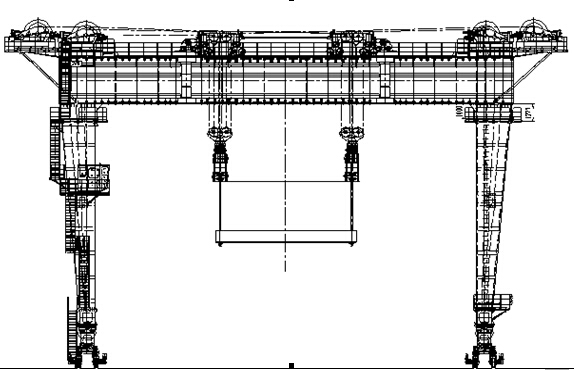

1200t gantry crane takes PLS as main control box, which is a kind of industrial touch screen with human-computer interface, providing direct method to alarm for system failure. All motor drives adopt AC variable frequency speed regulation technology, so that it can realize soft start and stop in any working condition. Wireless remote control device is also a kind of convenient control method.

2. How to diagnoze and maintenance system failure?

Electric control system adopt advanced PLC and touch screen methods, it shorten the time of testing and estimating when there is something wrong in the gantry crane. PLC can finish real-time detection for all kinds of malfunctions. Should failure occur, automatically, PLC will play a part in leading the equipment safe shut-down and keep the failure situation. Meanwhile, operators will see the reason showed on the touch screen. After that, the maintainer can test and repair the crane according to the reminder.

3. Routine inspect for electric system is necessary.

A routine examine of electric system before starting up is indeed necessary. Besides, it is also sensible to inspect each electric terminal to ensure fastening of the contacts.

Note:

1. It is not allowed to dismantle any electric limit switch.

2. It is not allowed to change the technical parameters for frequency converter.

ZZHZ Ralated Hoist and Construction Machinery:

gantry crane, overhead crane, bridge building crane, concrete batching plants, concrete spraying system, backhoe loader

Email: zzhz114@gmail.com Tel: 0086-371-68000000